A List of Measuring Equipment Manufacturers Use During Their Operations

14 April 2023

Manufacturing companies can only produce quality output out of their operations if they utilise the right tools and equipment pieces. Various measuring equipment pieces are only some of the tools they must use to generate valuable parts and components.

There are many reasons why manufacturers should invest in measuring equipment pieces. First, measuring equipment pieces enable manufacturing companies to meet specific quality standards, generating products that are consistent and free from defects. These companies also use measuring tools to ensure consistency in terms of product size and shape, meet customer specifications, guarantee product safety, and improve their efficiency. Even the costs of their manufacturing processes can be minimised with measuring tools.

Various types of measuring equipment can be utilised in manufacturing operations today. Some examples of measuring equipment pieces manufacturers use are as follows.

Callipers

Callipers are measuring tools used to accurately measure the distance between two opposite sides of an object. They have two arms that allow proper fitting of the object being measured. The arms are connected by a hinge so they can move relative to each other. One of the arms has a graduated scale, while the other arm has a sliding jaw. Callipers are used by adjusting their sliding jaw to fit the object being measured and reading the scale on the graduated arm, which helps determine an object’s inside and outside dimensions. This tool can also determine the depth of holes or grooves, the thickness of materials, and the diameter of small objects.

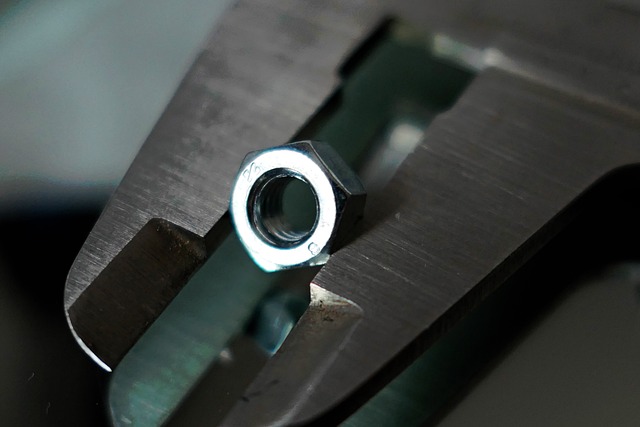

Thread Gauges

Thread gauges are measuring tools that can be utilised in measuring the pitch, diameter, and other characteristics of threads on screws, bolts, and other threaded components. They can make sure that these elements are within specified tolerances. They come in various types, which include plug gauges, ring gauges, and thread pitch gauges. When using a thread gauge, one must insert it into the threaded hole or over the threaded bolt or screw. The tool must then fit snugly over the threads if they are within the specified tolerance.

Micrometres

Micrometres are measuring instruments that can measure the dimensions of small objects with high accuracy. They are comprised of a measuring spindle, which moves relative to a stationary anvil. The spindle is linked to a thimble with evenly spaced markings to represent units of measurement. It then moves in and out of the micrometre frame by turning the thimble. When using this tool, one should open the micrometre jaws and place the object being measured between them. The thimble must then be turned until the spindle interacts with the object being measured. The user can, ultimately, read the measurement from the thimble.

Dial Indicators

One last measuring tool that manufacturers may use is a dial indicator. Dial indicators or dial gauges are precision measuring tools that can measure small distances or displacements with high accuracy. They are integrated with a spring-loaded plunger that can move in and out of housing once pressed against an object. The plunger is linked to a dial that can display the distance or displacement of the plunger. The dial indicator can be used by attaching it to a fixture or stand that can hold the object and subsequently reading the dial measurement.

As technology continues to advance, more measuring equipment may continue to emerge. But by using these tools, you can already ensure the accuracy and quality of your products, which can help you build a reputation for quality and reliability in the marketplace.

Optimized by: Netwizard SEO