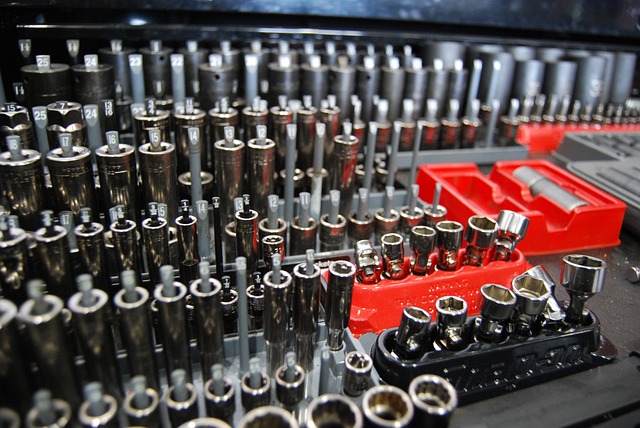

Pick the Right Sockets and Impact Sockets for Your Application

16 May 2023

Sockets and impact sockets can help tighten and loosen bolts and nuts, which is why they should be picked correctly to prevent damaging these components.

Bolts and nuts can only be tightened and loosened if the right sockets and impact sockets are maximised. These tools are often made from high-quality materials and come in a wide range of sizes and shapes to suit different mechanical and industrial applications.

A ComparisonBetween Sockets and Impact Sockets

Sockets are a type of wrench designed to fit over the head of a bolt or nut, allowing the user to apply torque to the fastener. They come in a variety of sizes and shapes, including hexagonal, square, and Torx. They can then be used with a ratchet, breaker bar, or torque wrench for added leverage and control.

Impact sockets, on the other hand, are a type of socket that can work with impact wrenches or air-powered tools. They are made from tougher materials than regular sockets to withstand the high torque and vibration produced by impact wrenches. These tools have a deeper and wider socket profile to prevent rounding or damaging the fastener.

Factors to Consider in Picking the BestSocket Type

Both sockets and impact sockets come in a variety of sizes and shapes, and they are typically available in sets or as individual pieces. They are alsocolour-coded or labelled for easy identification and may be marked with the size of the socket in both metric and imperial measurements.These differences allow you to pick the right one for your application.

Here are some things you must consider when selecting one for your application.

• Socket Size and Type: Sockets come in different sizes. Common socket sizes include 1/4 inch, 3/8 inch, 1/2 inch, and 3/4 inch. Knowing the size of the fastener is essential so you can opt for the correct socket size. The type of socket will also depend on the fastener you are working on. Some types of sockets include standard, deep, and spark plug sockets.

• Material:Sockets can be made from different materials, including chrome vanadium steel, chrome molybdenum steel, and carbon steel. Chrome vanadium steel is the most used material for sockets because it is strong, durable, and resistant to rust and corrosion. Chrome molybdenum steel is stronger than chrome vanadium steel and is used for applications that require more torque. Carbon steel is a lower-cost option but is not as durable as chrome vanadium or chrome molybdenum steel.

• Impact vs. Standard Sockets: Impact sockets can handle the high torque output of impact drivers and wrenches since they are made from a more durable material than standard sockets. They can also withstand the force of impact tools without cracking or breaking. Standard sockets, alternatively, might not be able to handle the high torque output of impact tools and may even crack or break under the force of impact tools. If you are using an impact tool, always use an impact socket to avoid damaging the socket or injuring yourself.

• Impact Socket Thickness: When choosing impact sockets, the thickness of the socket wall is an important consideration. Thicker socket walls can handle the force of impact tools and can withstand the stress of repeated use. Thin-walled sockets are more susceptible to cracking or breaking under the force of impact tools. Make sure to choose an impact socket with a thickness that is appropriate for your application.

Choosing the right sockets and impact sockets can help you ensure that your job is done efficiently and safely without damaging the fastener or the socket or injuring yourself. You should get one from a reputable supplier to prevent application failures.

Optimized by: Netwizard SEO