Reduced Shank Drills vs. Standard Drills: Choosing the Best Option for Heavy-Duty Metal Drilling

10 March 2025

Newlands Fasteners & Engineering Supplies offers premium reduced shank drills and tools, ideal for heavy-duty drilling applications in any industry.

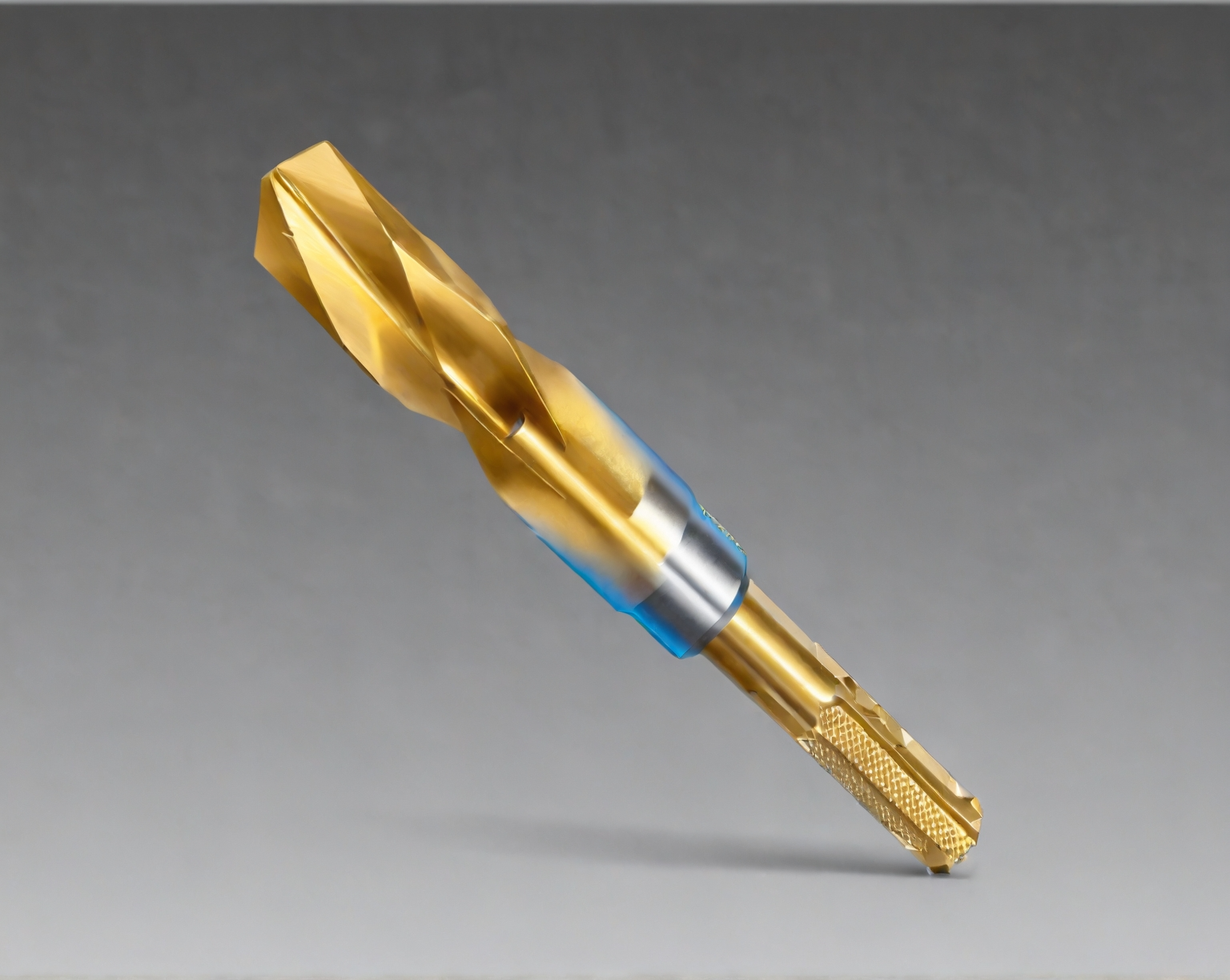

Reduced shank drills are engineered to deliver enhanced strength and precision, particularly in heavy-duty metal drilling tasks. Designed for demanding applications, these drills are built to maintain accuracy while handling tough materials. For industries requiring high performance and durability, reduced shank drills offer a distinct advantage in drilling efficiency and overall quality.

General Metal Drilling with Standard Drills

Standard drills serve as an economical and reliable option for general metalworking tasks, particularly in lighter applications. Though less suited for high-stress conditions, they are essential tools for a variety of routine tasks that don’t require the added durability of specialised drills.

1. Cost-Effective for Routine Applications: Standard drills are a budget-friendly option for general metal drilling tasks, offering reliable performance for businesses with less demanding workloads.

2. Widely Accessible and Versatile: Available in various sizes, standard drills are suitable for a wide range of softer metals like aluminium and brass, making them a versatile tool across industries.

3. Less Maintenance Required: Standard drills require minimal upkeep, with only basic cleaning and sharpening needed to maintain consistent performance over time.

4. Ease of Use for Different Users: Their simple design makes standard drills easy to operate, ensuring efficiency and reducing the risk of errors for workers with varying skill levels.

5. Ideal for Non-High-Pressure Tasks: Standard drills excel in tasks where speed and cost efficiency are priorities, without the need for extreme precision or durability.

6. Effective for Light to Medium Materials: Standard drills are perfect for drilling softer metals and alloys, providing ample power without excessive wear or damage.

7. Reliable for General Purpose Drilling: Standard drills offer dependable performance for everyday metalworking tasks, making them a reliable option for general fabrication and automotive industries.

8. Consistent Performance for Everyday Tasks: Standard drills maintain steady performance under regular conditions, making them a go-to choice for routine applications in various industries.

Reduced Shank Drills vs. Standard Drills: Assessing Roles in Challenging Drilling Conditions

The unmatched precision and stability that shortened shank drills provide when drilling with challenging materials makes them an obvious advantage in high-pressure drilling scenarios. In heavy-duty applications, their design minimises deflection, allowing for deeper and more precise drilling in hard metals. Standard drills, on the other hand, require more regular maintenance and replacements since they exhibit heightened wear under high torque and, although sufficient for routine jobs, frequently lack the strength required for demanding activities.

The reduced shank drills allow compatibility with smaller chucks without compromising the drill’s strength or performance. Standard drills, however, are often unable to maintain the required durability and precision under sustained high torque. The reduced shank drill stands as the superior option, excelling in both performance and longevity, making it the preferred choice for heavy-duty drilling tasks.

Ensure Excellence in Every Drill with Newlands Fasteners

Newlands Fasteners & Engineering Supplies is a trusted supplier of premium fasteners and engineering tools, specifically designed to meet the rigorous demands of heavy-duty drilling applications. Drawing on over 60 years of industry expertise, we are committed to providing dependable products and exceptional service to support the specific needs of your business. Set your business up for success with our best-in-class fasteners and tools, tailored to deliver exceptional results in heavy-duty drilling.

Optimized by: Netwizard SEO