Tap Wrenches for Accurate Thread Cutting in Your Manufacturing Workflows

13 May 2024

Optimise thread cutting in your manufacturing processes with tap wrenches from Newlands Fasteners. Explore their importance and uses for precise thread work.

Thread cutting with tap wrenches is a fundamental process in manufacturing, essential for creating threaded components that are used in a wide range of applications. This process helps in producing accurate and quality bolts, screws, or pipe fittings. Tap wrench, a versatile tool designed to facilitate precise and efficient cutting of internal threads, can be useful in achieving accurate thread cutting results as long as it comes from Newlands Fasteners.

Function and Design of Tap Wrenches

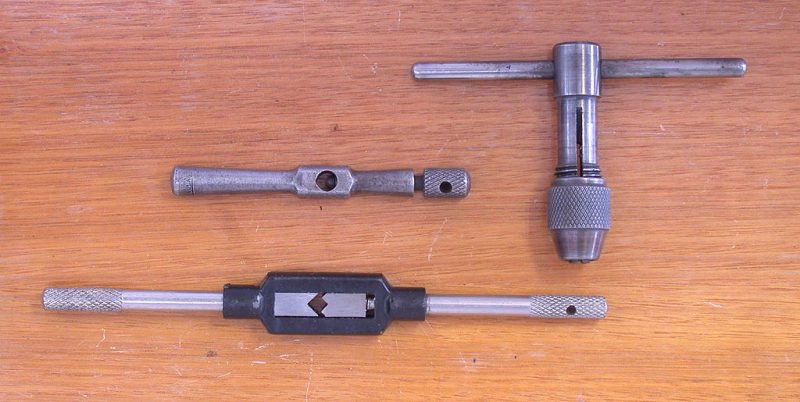

Tap wrenches are hand tools used to hold and manipulate taps, which are cutting tools used to create internal threads in a variety of materials, including metal, plastic, and wood. They come in a range of sizes and designs, but they generally feature a T-shaped handle with adjustable jaws or collets to securely grip the tap during the cutting process. Some tap wrenches also integrate ratcheting mechanisms or adjustable clutches to facilitate smooth and controlled rotation.

Using Tap Wrenches in Thread Cutting

Using tap wrenches in thread cutting offers several key benefits that make them indispensable in manufacturing workflows. These benefits are as follows.

• Precision Control: Tap wrenches provide operators with precise control over the cutting process, allowing them to apply the optimal amount of force and rotation to produce accurate threads with tight tolerances. This level of control is essential for achieving consistent results and ensuring the integrity of threaded components.

• Durability and Reliability: Constructed from high-quality materials such as hardened steel or alloy steel, tap wrenches are built to withstand the rigours of industrial use and provide long-lasting performance in demanding manufacturing environments. Their robust construction guarantees reliable operation and minimises the risk of tool failure or breakage during thread cutting operations.

• Versatility: Tap wrenches are compatible with a wide range of tap sizes and types, making them versatile tools that can be used for various thread cutting applications. Whether it’s creating coarse or fine threads, metric or imperial sizes, tap wrenches can accommodate diverse threading requirements, enhancing the flexibility and efficiency of manufacturing processes.

These benefits of tap wrenches make them useful in manufacturing processes across numerous industries. In metalworking, they can be used to create internal threads in metal components such as bolts, nuts, and machine parts. These tools can also be employed for cutting threads in pipes and fittings for plumbing installations and repairs. Tap wrenches can likewise be maximised for tapping threads in wooden dowels, furniture components, and cabinetry.

Key Practices for Tap Wrench Operation

To maximise the effectiveness of tap wrenches in thread cutting, they must be used properly.

For one, they must be properly aligned with the workpiece to prevent cross-threading or misalignment. They must also be used alongside cutting lubricants or coolants to reduce friction and heat generation during cutting, prolonging tool life and improving thread quality. Consistent pressure and rotation must likewise be applied when using these tools to achieve uniform threads with smooth finishes.

Tap wrenches, which you can get from Newlands Fasteners, can help achieve accurate and precise thread cutting in manufacturing workflows. From their precision control and versatility to their durability and reliability, they can ensure the quality and integrity of threaded components in many industries.

Optimized by: Netwizard SEO